THE PROBLEM:

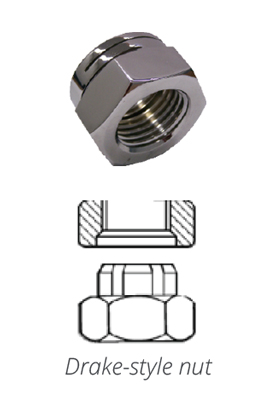

A large compressor manufacturer traditionally fastened valve plates with a Drake-style locknut. Drake nuts enabled operators to achieve desired preload with precision.

However, there were drawbacks:

- Two-piece assembly required operators to be familiar with a specific installation procedure.

- Multiple tools were needed to ensure torque was applied correctly. This increased operator error.

- Limited availability, long lead times, and high prices.

THE SOLUTION:

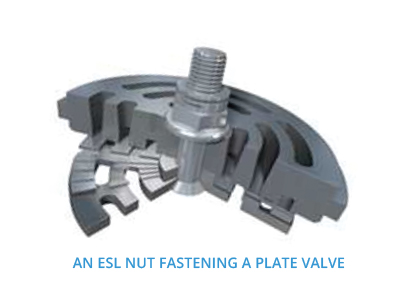

Following extensive testing and evaluation, the customer approved the J.Lanfranco ESL nut across the board for its plate valves. The superior performance of the ESL led to major improvements in key areas:

- A one-piece locking nut that does not require specific knowledge or multiple tools for installation.

- A locking fastener with prevailing torque that functions independently of any preload.

- 100% perpendicularity when required.

- Consistent prevailing torque that enables exact bolt tension to be achieved with each installation.

- No galling and consistent friction coefficients for stainless steel. It uses a permanent, cost effective, anti-galling treatment that’s been factory applied.

After changing to ESL nuts, the customer experienced the following benefits:

- 50% faster installations.

- Reduced inventory. The ESL’s single piece replaces the two pieces previously stocked.

- One piece for operators to work with. Eliminates mix-ups when matching tops and bottoms.

- No galling in stainless steel joints.

- Better availability and certification.