While some customers order their nuts in a plain finish, most will want some type of corrosion-resistant surface treatment. To meet your various needs and specifications, we offer a huge selection of in-stock parts with different surface treatments: electro-deposited zinc (trivalent and hexavalent), mechanical zinc, zinc flake, and hot-dip galvanized. If you’re not sure which surface treatment is best for your application, contact us and we’ll help you figure it out.

ZINC PLATE (HEXAVALENT)

ZINC DICHROMATE PER ASTM B633:

Good old yellow zinc. Whether in Sc.1-2-3 or types 1-2-3-4-5, we’ve got you covered. A staple for many years, we continue to produce a variety of safety-critical locknuts in this finish. It provides basic but effective corrosion resistance (in the 96 hours to red rust range) in thicknesses that ensure standard thread fit.

OLIVE DRAB, ASTM F1941 D:

Olive drab still shows up occasionally. When we do it, the finish comes out looking army green. Although rarely specified across the board nowadays, we still see legacy designs using it on new builds, so we continue to provide it, typically on nylon insert locknuts stocked 1⁄4″to 1″1⁄4.

ZINC PLATE (TRIVALENT)

TRIVALENT CLEAR ZINC:

Standard trivalent clear zinc provides basic corrosion resistance of 96 hours salt spray to red rust.

ZINC LANTHANE AND TOPCOAT:

This is our most popular electro-deposited zinc finish and has a clear and shiny appearance. With standard thicknesses of 8-11 microns, it ensures standard thread fit, +600 hours salt spray to red rust performance, and has a guaranteed CoF of 0.15 +/- 0.03. It’s also RoHS and REACH compliant. This is an excellent option for parts requiring good thread fit, consistent CoF, and superior corrosion resistance (compared to traditional zinc finishes).

ZINC NICKEL AND TOPCOAT:

An often overlooked zinc plating, this is an excellent option for areas subjected to debris that will chip or damage surface treatments. It has an average thickness of 8 microns and approximately 12-15% nickel content. This zinc plate will provide a minimum of 750 hours salt spray to red rust performance, while providing a harder surface to withstand the harshest conditions. Also available with a topcoat to provide a guaranteed CoF of 0.15 +/- 0.03. Zinc nickel will show a variety of hues, depending on bath concentration and time in storage. This is normal and will not affect performance.

ZINC FLAKE (LAMELLAR ZINC)

GEOMET:

This is one of the most popular zinc flake coatings today. Available in 320 A & B and 500 A & B, GEOMET is a zinc flake coating that can be applied using a dip/spin method or a rack/hang/spray method. Advantages include very high corrosion resistance (600-1000 hours salt spray) with a thin coating, guaranteed CoF inherent with GEOMET 500 (320 requires the addition of a topcoat), and no risk of hydrogen embrittlement. GEOMET and similar zinc flake coatings are typically used where the risk of hydrogen embrittlement is elevated (when high-strength steel parts are exposed to traditional electro-deposited zinc plating processes).

NOTE:

Despite carrying a high corrosion resistance rating, GEOMET and similar zinc flake coatings should be handled and installed with care to avoid chipping the finish. This will allow corrosion to migrate underneath.

MAGNI 565-575:

This is a very popular zinc flake coating with similar properties as GEOMET and Delta Protekt. Much more prevalent in North America, it typically uses a slightly thicker application.

DELTA PROTEKT:

A popular zinc flake coating available on our fasteners. Minimum lot charges may apply.

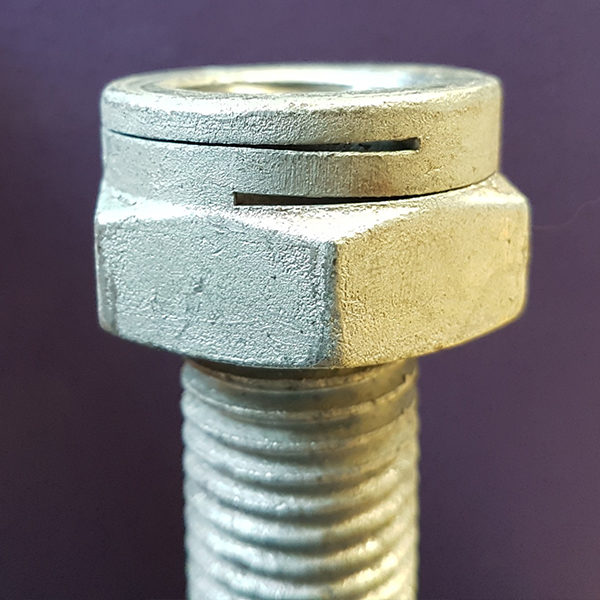

HOT-DIP GALVANIZED

This is the “granddaddy” of surface treatments. Typically stocked in metrics and some limited imperials, all nuts are over-tapped to ensure the best possible fit. If you plan to leave something for 100 years without doing any maintenance, this may be your solution.

Usually, when using a nut/bolt assembly that has been hot-dip galvanized, the nut will be over-tapped (ASTM A563, table 5) to accommodate the additional thickness the HDG will add to the bolt threads. Depending on the precision of your application, it’s advisable to verify the over-tap required to ensure consistent thread fit.

One little-known fact is that European customers will also specify an under-tap on the bolt to maintain standard tapping on the nut. If using metric HDG fasteners, be sure to verify which fastener (nut or bolt) needs to be over- or under-tapped.

STAINLESS STEEL ANTI-GALLING

PLAIN:

Good old plain stainless steel… Just what we’re used to seeing.

PASSIVATE:

One of the main finishes in our stainless steel line. Preferred by customers working in the food and agricultural industries, as well as others looking for a classic stainless steel finish.

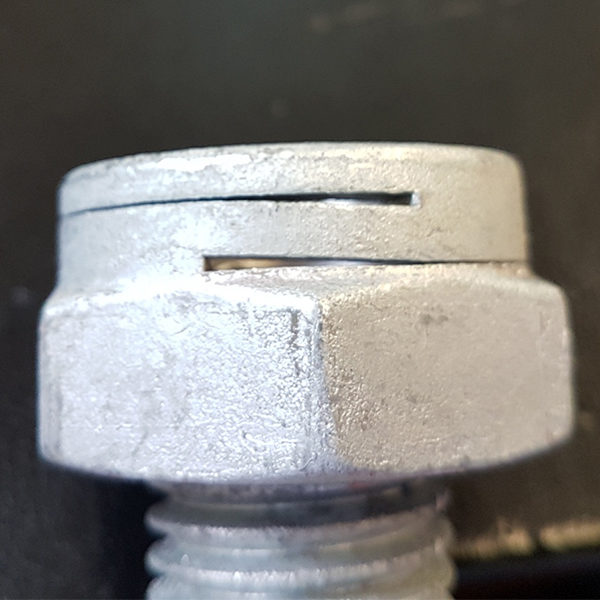

ANTI-GALLING:

We’re not talking about some generic wax or lubricant. The majority of our stainless steel locknuts receive a permanent anti-galling surface treatment which is diffused at 400°C and actually enters the surface of the metal. The result: No galling, no need for anti-seize pastes or lubricants, and guaranteed CoF of 0.15 +/- 0.03. Coupled with our dual-locking slots, seized up installations are a thing of the past.