Case Studies

J.Lanfranco locknuts are used by various industries to improve equipment integrity and operational efficiency. Have a look at our case studies below.

J.LANFRANCO KEEPS IT FLOWING FOR THE OIL AND GAS INDUSTRY

THE PROBLEM:

A manufacturer of compression check-valve was experiencing a high frequency of nuts seizing up during installation and removal for maintenance. Anti-seize pastes and greases couldn’t be used due to in-service contamination.

Major issues included:

- Sorting and verifying locknuts prior to installation led to an increase in labor costs and resulted in lost material for failed nuts.

- Using anti-seize pastes and greases wasn’t an option because of potential chemical reactions or contamination that could occur while in service.

- Customers couldn’t remove the nuts to perform required maintenance. This created increased downtime and high warranty costs for the OEM.

- As costs mounted, the OEM searched for a solution to improve installation efficiency and eliminate maintenance issues.

THE SOLUTION:

The ESL nut, in stainless steel 304L passivated, was tested on 300 valves. ESL nuts provided:

- Better locking performance.

- No seized nuts during installation or maintenance.

- Increased re-usability.

- Elimination of warranty claims related to locknuts.

- Following customer feedback, the OEM decided to outfit all of its major valves with ESL nuts. Today, nearly 150,000 valves are produced annually using ESL nuts.

J.LANFRANCO PROVIDES THE PRECISION, EFFICIENCY, AND DURABILITY REQUIRED BY THE MILITARY

THE PROBLEM:

Long approved by defense contractors for a wide range of applications: Leclerc tanks, computer and electronic cribs for Lockheed Martin, high-speed winches for Navy choppers. J.Lanfranco ESL locknuts have provided dependable performance for security-grade military bolted joints.

Vehicle-mounted weaponry must not only resist high vibration during service, but also allow for in-field adjustments and maintenance without needing access to a full shop. One major hurdle in accomplishing this is the frequency of galling that occurs in all stainless steel applications. This is the case for precision machine gun sights. Because of the severe vibration generated by large caliber vehicle-mounted machine guns, sights must be adjustable in the field while maintaining that adjustment during intense service conditions.

THE SOLUTION:

The ESL was tested and approved because it ensured:

- Locking independent of bolt tension.

- Ability to resist shock and impact.

- No inserts to break down.

- Impervious to corrosion, heat, and chemical agents.

- No galling or damage to bolt threads.

All of these factors allow weapons to perform accurately without incident. They also ensure multiple adjustments with no degradation to the threaded rod portion of sights.

J.LANFRANCO KEEPS TRANSIT AGENCY ON TRACK

THE PROBLEM:

A major North American transit agency was experiencing loosening of their track work fasteners. This was due to modern vehicles coming into revenue service, and generating much higher shock and impact in turnouts.

The loose nuts and bolts created many issues:

- Public safety concerns.

- Increased frequency of maintenance inspections.

- Disruptions to revenue service.

- Higher overall operational costs.

- One of the main requirements was a one-piece part with a captive disc spring washer that can be installed with standard tools and bolts. And most importantly: Stay tight without loosening.

THE SOLUTION:

J.Lanfranco supplied ERM nuts in ⅞”-8UNC Gr.5. After several months of testing, there was no loosening and a routine inspection and maintenance schedule was re-implemented. This solution led to increased security and reduced operational costs.

The ERM also ensured:

- Quicker initial installations.

- Reduction of parts, and no forgotten or lost washers.

- Fewer inspections required after installation.

- Torque can be re-applied with hand tools (no power source is needed on-site).

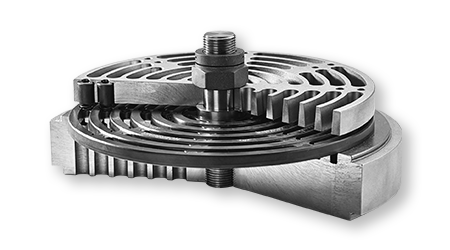

PLATE VALVES: IMPROVE INSTALLATIONS & RELIABILITY

THE PROBLEM:

A large compressor manufacturer traditionally fastened valve plates with a Drake-style locknut. Drake nuts enabled operators to achieve desired preload with precision.

However, there were drawbacks:

Two-piece assembly required operators to be familiar with a specific installation procedure. Multiple tools were needed to ensure torque was applied correctly. This increased operator error. Limited availability, long lead times, and high prices.

THE SOLUTION:

Following extensive testing and evaluation, the customer approved the J.Lanfranco ESL nut across the board for its plate valves. The superior performance of the ESL led to major improvements in key areas:

- A one-piece locking nut that does not require specific knowledge or multiple tools for installation.

- A locking fastener with prevailing torque that functions independently of any preload.

- 100% perpendicularity when required.

- Consistent prevailing torque that enables exact bolt tension to be achieved with each installation.

- No galling and consistent friction coefficients for stainless steel. It uses a permanent, cost effective, anti-galling treatment that’s been factory applied.

After changing to ESL nuts, the customer experienced the following benefits:

- 50% faster installations.

- Reduced inventory. The ESL’s single piece replaces the two pieces previously stocked.

- One piece for operators to work with. Eliminates mix-ups when matching tops and bottoms.

- No galling in stainless steel joints.

- Better availability and certification.

J.LANFRANCO IS CALLED UPON TO KEEP TRANSIT BUSES ON THE ROAD

THE PROBLEM:

As modern manufacturing is streamlined, integration of composite and other materials increases the need for efficient installations. This is essential in managing labor costs and expensive re-outfitting of poorly fitting parts.

A large bus OEM required the ability to perform a blind installation and driver seat adjustments on a fleet of buses. The traditional method of mounting the driver seat and removing it for maintenance required two mechanics, with one underneath the vehicle. This presented several problems:

- Expensive installation process.

- Dedication of two mechanics.

- Difficult maintenance change out.

- Difficult to access underneath the bus.

- No adjustability to accommodate future design changes and improvements.

THE SOLUTION:

J.Lanfranco produced a modular fixture with three ESL nuts, each ⅝UNC Gr.8 mounted over a total span of 18” and a total movement of +/- ½”.

Two J.Lanfranco modular fixtures were installed underneath each seat platform on the chassis. The seat was then installed blindly by one mechanic inside the vehicle. The ½” travel of each nut ensured that, regardless of slight changes by the seat manufacturer, the change out will always be quick, safe, and efficient.

J.LANFRANCO IS ABLE TO SHAKE, RATTLE, AND ROLL WITH THE MINING AND PROCESSING INDUSTRY

THE PROBLEM:

Shaker tables are subjected to some of the most demanding operating conditions: Intense shock, impact, and vibration. They’re often the bottleneck of mining operations since premature loosening of screens cause unplanned shutdowns.

Unscheduled screen change outs result in:

- Reduced plant throughput.

- Reduced profitability.

- High labor costs.

- Increased warranty costs for screen OEMs if minimum run cycles are not met.

THE SOLUTION:

Numerous customers have switched over to both ESL and ERM locknuts for in-operation performance, as well as for the ease and speed of change outs.

One customer in particular required a Gr.8 ERM nut 3/4UNC with a crimped washer that would provide:

- Easy initial installation with no galling.

- Ability to loosen and re-tighten without full removal for quick change outs.

- No damage to bolt threads.

- Washer retention to withstand +10,000lbs of force.

They also needed the first parts within three weeks. It took some effort, but The Nut Jobs at J.Lanfranco came through. Drawings and CAD files were submitted within one week, and the first 700 pieces were produced and delivered within two weeks. The ERM nuts provided the customer with 10 on/offs and met all criteria.